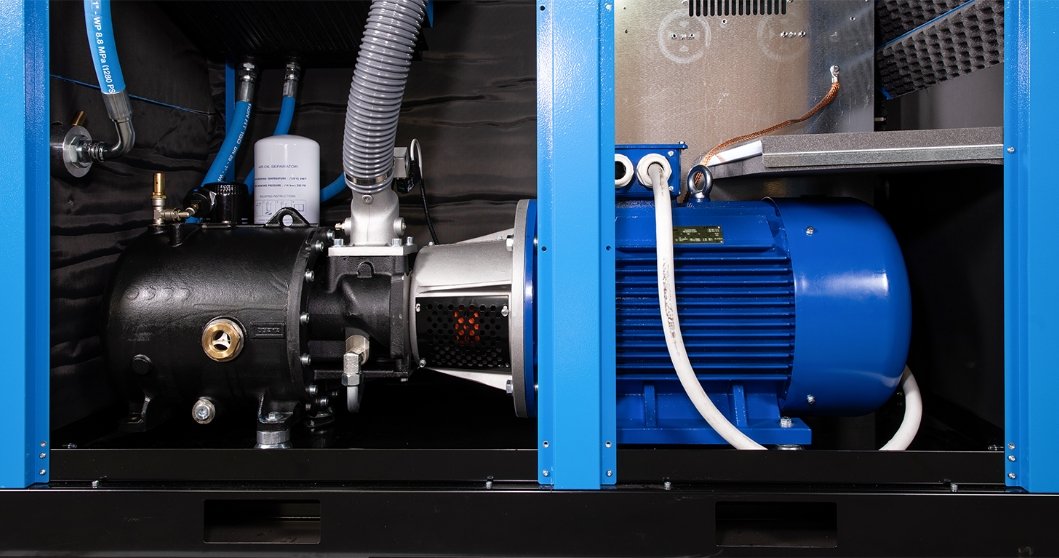

The electric motor used by the compressor is a PREMIUM EFFICIENCY IE3. This ensures its efficiency exceeds and complies with the minimum efficiency requirements (MEPS). This first-class performance guarantees energy savings over time and the best-in-class reliability of a high-standard certified product.

The belt drive system is engineered to guarantee driving stability during a work phase and off-load cycle. The plate system with a sliding electrical motor is designed to prevent stress on rotating parts. Our machine, with a poly-v belt-driven system with cast-iron taper-hub pulleys, ensures the utmost reliability in any work condition and limits power loss. An easy system of belt-tightening allows an accurate adjustment of the belt itself.

The FC ranges are fitted with a professional grade double-thickness soundproofing foam with fire retardant and oil-resistant materials for maximum protection and easy cleaning.

Based on direct, user-friendly reading, all machine functions are run safely through a microprocessor, from the control of safety alarms (oil temperature, electrical engine, control of cooling electrical fan, maintenance time) to command systems (start-stop, alarm rest). Access to all microprocessor functions is protected by a password (supplied only to authorised staff).

The FC series includes a mounted pre-filter that guarantees the protection of internal components by filtering all the machine air intake from dust, dirt, shavings, and pollutants that would prematurely clog the air filter. A high flow-rate electrical fan, almost noise-free, circulates and pushes all airflow into just one point, ensuring the right thermal balance for all the internal components.

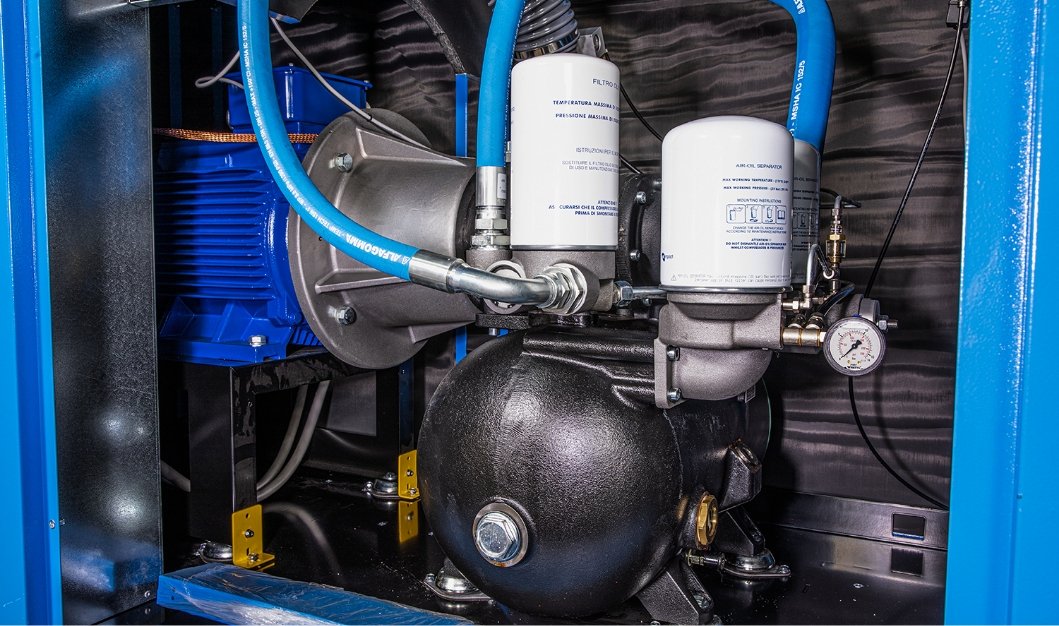

With a large intake and exchange surface, the FC series is designed for maximum heat exchange efficiency, therefore regulating the running temperature of the air compressor. With aluminum, vacuum-brazed coolers, and multiple fins, we can ensure effective heat dissipation through the compressor.

A rigid design structure allows for less vibration and less noise in a compact design. The common base frame is designed for easy handling with a forklift.

Stainless steel tubes have been widely used in the piping design of these air compressors to protect piping from rust. The piping layout results in a neat appearance and ease of maintenance.

Fill in your details below and we’ll be in contact shortly.

Quick Links

© Focus Industrial 2024. T&Cs. Sitemap

STAY IN THE LOOP

Join our mailing list and get first access to your offers, new products and more!

Focus Industrial

Copyright 2021 | All Rights Reserved

OUR PRODUCT SPECALIST ARE STANDING BY TO DELIVER YOUR QUOTE IN UNDER 24 HOURS!